From cloud computing to managing databases, knowledge facilities are important for functions comparable to cloud providers, e-commerce, buyer relationship administration techniques, on-line leisure, gaming, and digital banking.

Consequently, knowledge facilities have been rising quickly world wide, and this has resulted in a corresponding rise in general energy consumption.

AI processing, which harnesses the processing energy of modern microprocessors and graphics processing items, has taken power-consumption ranges in knowledge facilities to new heights. In accordance with a latest Worldwide Vitality Company report, electrical energy use in knowledge facilities will reach 945 TWh by 2030, almost double the 415 TWh in 2024.

The server rack inside the info middle typically has a goal energy consumption of around 1 MW. This enhance in rack energy will increase the current-handling functionality past the sensible limits of the current DC bus energy structure. For instance, to energy a 1 MW rack, as we speak’s 48 V distribution system would require over 20,000 amperes of present. The scale and value of the copper busbar to ship this present are unrealistic.

Consequently, accommodating the big power-processing calls for of AI workloads requires higher-voltage DC (HVDC) energy distribution techniques. Energy conversion requires superior management methods and excessive ranges of circuit integration to allow excessive effectivity and high-power density in an HVDC knowledge middle.

On this article, we’ll study the HVDC structure and talk about the kinds of expertise wanted to maximise effectivity and energy density.

HVDC Energy Distribution Methods

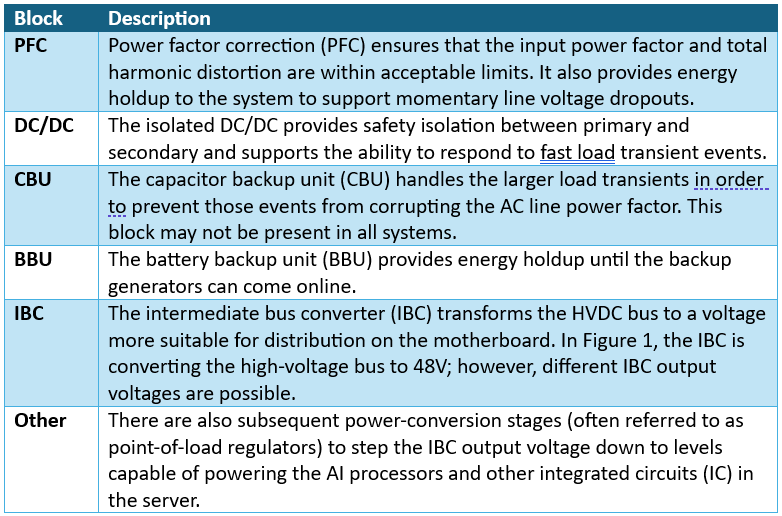

Determine 1 reveals the important constructing blocks of the HVDC system. Desk 1 lists a short description of every block.

Determine 1: Constructing blocks of the HVDC energy distribution system.

Desk 1: HVDC constructing block descriptions.

Having an in depth dialogue of every of the blocks in Determine 1 could be an unbiased paper all by itself. So, for simplicity, I’ll deal with the PFC and the DC/DC blocks and spotlight applied sciences instrumental in every to realize excessive effectivity and excessive energy density.

PFC

The PFC should have the ability to course of greater than 30 kW to succeed in the focused energy degree of 1 MW per rack. The PFC’s important goals are excessive effectivity, low whole harmonic distortion and excessive energy density.

Reaching these goals requires a classy real-time microcontroller (MCU) for the a number of suggestions loops within the system. The MCU additionally must report issues comparable to energy consumption to the host system. This MCU will want to have the ability to management the turn-on and turn-off of the power-conversion switches and gather and course of crucial system-level knowledge.

Examples of crucial system-level knowledge embody enter voltage, enter present, output voltage, output present, and field-effect transistor (FET) temperatures. In some circumstances, subtle management methods could also be essential to maintain effectivity excessive at elevated switching frequencies. One such management method is the triangle present mode (TCM)-controlled PFC. This kind of PFC controls the ability switches in such a approach as to realize zero voltage switching (ZVS) on each switching cycle, in any respect enter voltages and all load situations.

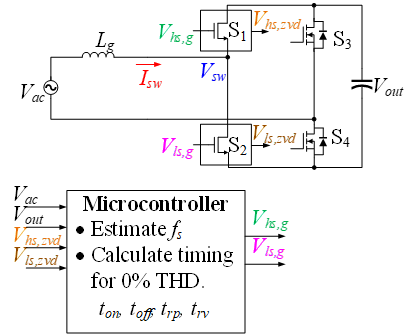

Determine 2 is a fundamental block diagram of a system with this sort of management, made potential with an MCU together with gallium nitride (GaN) switches for S1 and S2. GaN affords each low output capacitance and the flexibility to attenuate each turn-on and turn-off associated switching losses. The GaN proven in Determine 2 has a further zero-voltage detection (ZVD) function that stories whether or not the change has turned on with ZVS or not, which allows the usage of a brand new, extra correct management algorithm for TCM that achieves effectivity of over 99% and energy density of roughly 120W/in3.

Determine 2: TCM PFC management block diagram.

DC/DC

The DC/DC stage additionally requires excessive effectivity and high-power density; nevertheless, the topology and management construction are very completely different from PFC. An inexpensive topology alternative for the DC/DC stage is an inductor-inductor-capacitor (LLC), which may obtain ZVS in any respect load situations. Environment friendly management of the DC/DC stage will even require a complicated MCU. As well as, the excessive switching frequencies and the necessity for ZVS additionally make GaN a beautiful choice. To get the LLC to control over an affordable load and enter voltage vary, frequency modulation will management the output voltage.

Controlling the LLC output rectifiers to approximate the habits of a great diode may be very troublesome. Small errors within the FET timing will end in further conduction losses and even reverse present stream. The configurable logic block, together with the ZVD and zero-current detection options out there in GaN switches, offers the MCU the required performance to make sure that the GaN switches approximate the habits of a great diode on a cycle-by-cycle foundation, whereas stopping reverse present and sustaining excessive effectivity.

Sensing, Gate Drive, and Bias

Limiting noise within the voltage and present measurements whereas sustaining excessive bandwidth is a crucial function for each PFC and LLC. To handle this, some voltage and present sensors digitize the sign on the supply of the measurement and report the info again by way of an remoted interface. This allows the transmission of measurements again to the controller utilizing digital noise methods slightly than a delicate analog sign.

In circumstances the place energy shouldn’t be out there for sign sampling, many of those voltage and present sensors can be found with built-in bias energy.

30kW of energy requires advanced topologies that drive many FETs. For instance, within the PFC, a three-level flying capacitor topology for a three-phase AC enter would require 12 FETs. Every FET will want its personal driver and supporting bias provide to effectively flip the FETs on and off at a excessive frequency. Likewise, the dual-output three-phase LLC would require 24 FETs with bias and isolation. Built-in isolators, remoted drivers and bias provide ICs allow environment friendly small-form-factor options. The mixing present in these isolators, drivers, and sensors does so much to attenuate the general footprint of those techniques, maximize effectivity, and cut back noise.