Dr. Han Seong-Tae’s crew at KERI’s Trade Purposes Analysis Division has developed the core expertise of “electron weapons,” the center of “electron beam welders,” which had been depending on imports for greater than 99%.

“Welding,” which will be stated to be the idea of trade, is the method of melting and becoming a member of varied supplies resembling metallic. Conventional welding makes use of warmth from an arc (a spark generated by {an electrical} discharge) or a laser. Electron beam welders, however, use the kinetic vitality of electrons to bond supplies collectively.

In different phrases, when an electron beam is radiated, electrons accelerated to a excessive voltage collide with the welded materials and the kinetic vitality is transformed into warmth vitality. The welded objects are joined to one another by the excessive warmth generated at the moment.

The benefit of electron beam welding is that it permits defect-free becoming a member of of thick supplies that might not be achieved with standard welding. Lately, within the period of the 4th Industrial Revolution, the manufacturing of cutting-edge units is required in varied fields.

Specifically, a better stage electron beam welder is changing into obligatory for particular functions resembling aerospace, protection, and nuclear energy. The combustor of the Nuri launch automobile, launched in 2021, additionally utilized an electron beam welder to flawlessly connect specialty metal supplies and parts.

Electron beam welding requires very excessive technical abilities, and Korea has been counting on imports of greater than 99% of associated gear from Germany and Japan. In consequence, there’s a danger of leakage of home superior expertise within the strategy of sustaining and repairing imported welding machines.

Seong-Tae’s crew’s achievement in fixing this downside was to attain native manufacturing of electron weapons and driving energy methods, that are the core of electron beam welders.

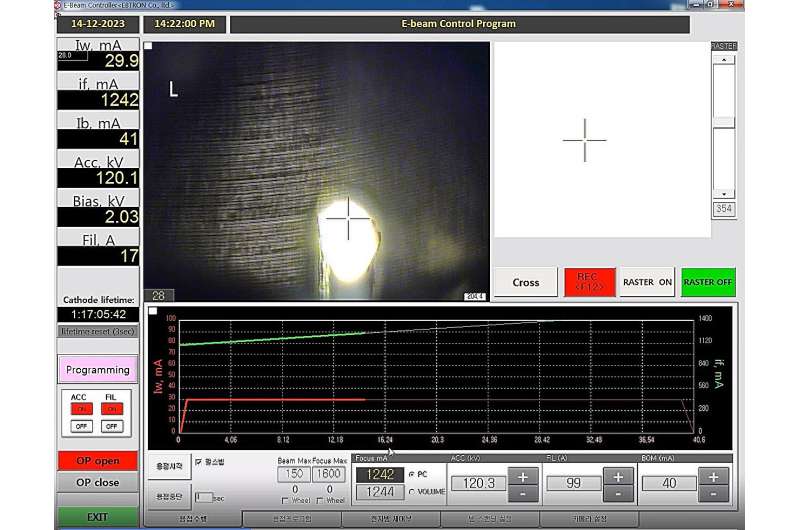

With electron beam welders, the upper the acceleration vitality of the electron weapons, the better the extent to which they’ll penetrate the warmth supply into the fabric. KERI’s expertise boasts world-class energy (60 kW) and accelerated voltage (120 kV).

It is a stage that may be utilized for machining nearly any thick, giant materials and half. The analysis crew put numerous effort into optimizing electrical and magnetic discipline constructions and minimizing voltage imbalance based mostly on high-voltage expertise collected over greater than 20 years to develop high-performance gear, and the efforts bore exceptional outcomes.

This achievement has opened the way in which for Korea to make use of electron beam welding with out dependence on overseas international locations. As a lot of the 12 nationwide strategic applied sciences that can lead the longer term require electron beam welding, it’s anticipated to have a big influence by way of the event of associated industries, impact of changing imported gear and prevention of expertise leaks.

Seong-Tae stated, “Because the trade strikes to excessive value-added areas, the demand for high-precision and high quality welding will improve, and there might be extra merchandise that can’t be manufactured with out electron beam welding.” He additionally added, “It’s also important in that it opens up a brand new avenue for home manufacturing of personalized, high-tech supply gear that solely high-performance electron beam welders can present.”

KERI, which has utilized for patents and printed abroad papers associated to the expertise, plans to develop ultra-high (170 kV or extra) and excessive present (500 mA or extra) electron weapons that may be utilized to next-generation small modular reactors (SMRs) by means of continued analysis.

KERI additionally goals to have management expertise that may carry out a number of features, together with metallic melting, materials hardening, floor remedy, and coating, to allow electron beam welding to be utilized in a wider vary of functions, together with 3D printing of complicated metallic constructions that require excessive power.

The findings are published within the journal IEEE Transactions on Plasma Science.

Extra data:

Seong-Ho Son et al, Improvement of 120 kV and 60 kW Three Part LCC Resonant Converter for Electron Beam Welding System, IEEE Transactions on Plasma Science (2023). DOI: 10.1109/TPS.2023.3288116

Quotation:

Korean researchers obtain native manufacturing of electron beam welding system (2024, March 5)

retrieved 6 March 2024

from https://techxplore.com/information/2024-03-korean-local-production-electron-welding.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.